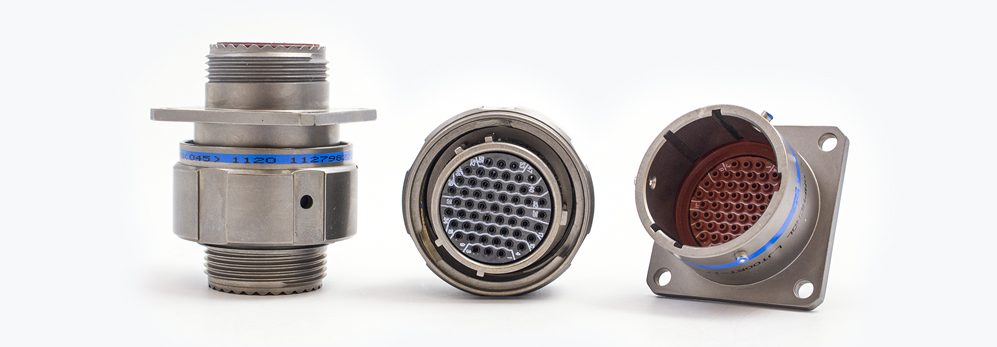

M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

MIL-SPEC connectors, also known as MS or Harsh Environment Connectors Standard Connectors, have been developed for tactical service and aerospace applications since the 1930s by the Harsh Environment Connectors. They have become a standard feature in other challenging industries, such as marine, aerospace, oil and gas, and various industrial and automotive environments. MIL-SPEC connectors are designed to withstand harsh conditions, and their durability depends on the specific application, including resistance to vibration, corrosion, or extreme temperatures.

These connectors consist of male and female headers. They are typically made from a phosphor bronze or beryllium copper alloy, with a highly conductive and non-corrosive metal, such as gold, used for plating. The connectors are usually a male plug connector with a ferrule for fibre optic connections, which holds and aligns the two fibres. It’s important to consider the insertion loss, measured in decibels (dB), which is the signal power or light lost during the connection.

When selecting MIL-SPEC connectors, there are some basic things you need to keep in mind. Product parameters include the number of contacts, type, size, connection method, housing specifications, and terminals.

The number of contacts defines how many conductive elements are present in a MIL-SPEC connector. These elements provide the electrical path when a connection is formed between two types of contacts (pins or sockets). Contact size is usually specified in AWG (American Wire Gauge) measurements and distinguishes the contacts from each other. This has a variety of different types of couplings available.

Connector housings are typically made of aluminum and are anodized or plated to prevent corrosion. Housings are available in a variety of styles, including

Standard connector housings are available in a range of sizes, starting at size 8 (0.50″) and increasing in 0.0625″ increments to size 36 (2.25″). Circular MIL-SPEC connectors have a cylindrical housing that increases in diameter size from 0.375″. MIL-SPEC connectors use threads to attach the backshell to the housing, typically equal to or within 0.062″ of the connector housing size.

Terminals can be attached to bolts, posts or other types of conductors to make electrical connections. Simple terminal devices include screws, lugs, cage clamps, wires soldered to a PCB, quick-connect tabs, and crimps. More complex terminals include inserting the connector into a solder cup or terminal and then soldering it to another metal surface. Or cut through the cable insulation with an IDC or insulation displacement connector.

This type of mass termination connector does not require stripping the insulation. Other types of connections use THT (through-hole technology) to mount components by pushing them through holes in the PCB. Or quick-disconnect lanyard release terminations. Solderless electrical connections can also use special wrapping tools to wrap the wires around the terminals.

MIL-C-5015: This general connector standard specifies the most popular types of circular connectors for use in commercial and Harsh Environment Connectors applications. The specification covers cylindrical electrical connectors with front and rear release contacts, made with removable crimp or solder contacts. These connectors are available in several grades with operating temperature ratings ranging from a minimum of -55°C to a maximum of 125°C, 175°C or 200°C.

MIL-C-22992: This is a connector standard for heavy-duty connectors supporting high power levels. This plug and socket electrical connector type is a multi-contact quick disconnect device. It is for Harsh Environment Connectors and industrial applications. Their rated operating temperature is -55°C to 125°C.

MIL-C-26482: For two series of environmentally resistant connectors with sealed receptacles and related accessories. These miniature circular connectors are of the quick-disconnect type. Typically found in Harsh Environment Connectors communication systems, I-Series connectors of this size offer excellent mechanical, electrical, and environmental performance in a compact design.

MIL-C-26500: It covers another group of miniature circular connectors designed to meet the environmental challenges of advanced missiles, rockets, aircraft, and space vehicles. The receptacle contact inserts for the plugs and sockets in these connectors have resilient faces, while the mating pin inserts are designated as having either hard or resilient faces.

MIL-C-27599: For two families of miniature circular connectors that are dense, environmentally resistant, and provide a quick-disconnect bayonet connection. This electrical connector can operate continuously from -65°C to 175°C. These MIL-SPEC connectors can interconnect with two series of MIL-C-38999 connectors.

MIL-C-38999: Includes four series of miniature, high-density bayonet, threaded or hip coupling, circular, environmentally resistant electrical connectors that use removable crimp or fixed seal solder contacts and are capable of operating over a temperature range of -65 °C to +200 °C. Connectable to MIL-C-27599.

MIL-DTL-5015 specifies the preferred connector for ground support and airframe requirements for the Harsh Environment Connectors aerospace industry. These post-release connectors have a reputation for reliability and combine the best features of several older models.

MIL-DTL-32139 specifies MIL-SPEC connectors for joint services managed by the U.S. Defense Supply Center (DSCC). It covers nanoscale micro connectors made of plastic and metal.

MIL-DTL-38999 covers four series of high-density, environmentally resistant miniature circular connectors with threaded, bayonet, or hip coupling. MIL-DTL-38999 connector type provides a fixed sealed solder or removable pressure contact point and can operate at temperatures from -65°C to 200°C.

MIL-DTL-83513 is another type of DSCC Joint Service Specification for Micro-D connectors with metal and plastic housings. It contains a revision of the original MIL-C-83513, changing its title to the DTL specification. The purpose of this is to adopt industry standards and performance-driven specifications.

MIL-DTL-83723 an umbrella standard that regulates environmentally resistant circular connectors, their contacts, and associated accessories. All MIL-DTL-83723 connectors are either crimp or solder contacts and must operate within the specified temperature range.

MIL-SPEC connectors are also available with special additional features for specific environmental applications.