M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

R&D Service We Provide

01

Professional engineer teams help you with drawing design and provide you suggestions based on your special electrical and environmental performance requirements.

02

Establish and optimize production line processes. Continuous improvement to ensure target quality yields are achieved and product quality is maintained.

03

With professional inspection center to test the electrical, mechanical and environmental performance and ensure the high quality of all the products we produce.

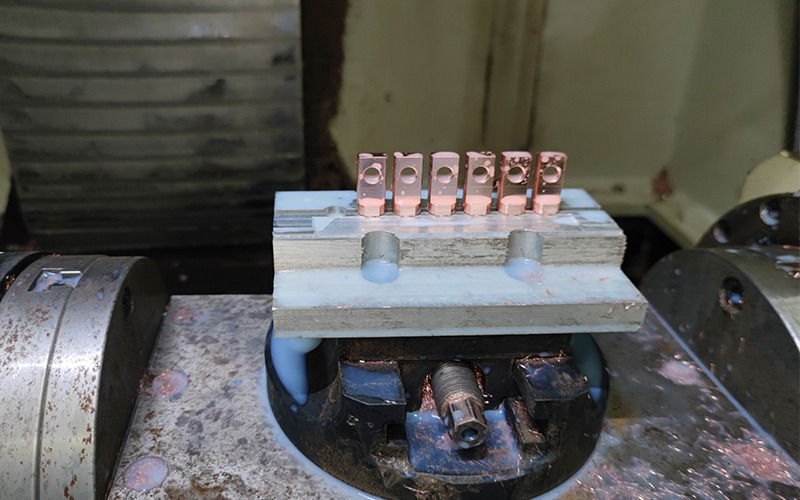

Tooling is an important field of metalworking for the manufacture of various types of metal and plastic parts. Our company specializes in designing high precision zinc alloy, aluminum alloy and plastic molds for connector production.

We are able to customize various types of molds according to the needs of our customers. We also use advanced equipment to support our tooling process to achieve high precision connector dimensional requirements.

Renhotec specializes in manufacturing metal and plastic components for electrical connectors through die casting and plastic injection molding. Our workshops are dedicated to producing high-quality parts, staffed with skilled personnel and leading-edge equipment.

Our focus on quality, precision, and efficiency ensures that we deliver exceptional components with unmatched performance and reliability. Trust us for your metal housing or plastic component needs.

Metal processing is a complex and precise manufacturing process that requires the use of advanced materials and techniques. We offer a wide range of metal processing solutions that cater to the needs of modern businesses. From CNC milling to metal turning, laser cutting and precision grinding, our skilled technicians are well-versed in all facets of metal processing.

We produce high-quality metal parts that are durable, reliable, and engineered to your exact requirements. So if you’re looking for a reliable partner with extensive experience in metal processing, turn to Renhotec.

Establish strict quality control procedures

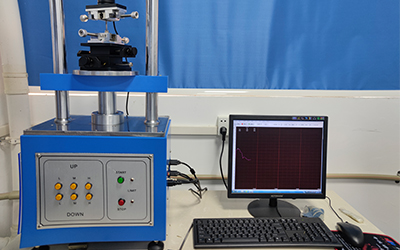

By applying a certain force to the connector plugging and unplugging process to simulate the plugging and unplugging load of the connector in the actual use process, to assess the reliability and stability of the connector in use.

By generating specific environmental atmospheres, such as salt spray and sea spray, the connectors are exposed to high concentrations of corrosive substances, to assess whether the surface coating and finish of the test product protects the substrate from corrosion and whether it maintains its proper function over time.

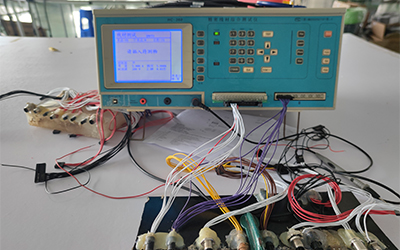

For measuring and detecting various parameters and physical quantities, ensuring high accuracy and stability of products.

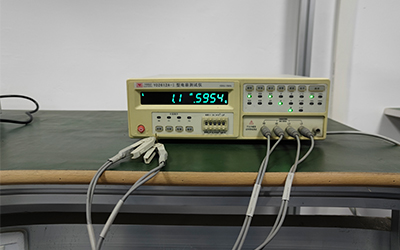

Determine if this connector is working properly by testing the capacitance value between the two connector pins. In this way, the connector can be tested quickly and accurately to ensure its reliability.

By projecting the object to be measured in the imaging system, the image is recorded and digitized to obtain parameters such as size, shape and position of the object to improve production efficiency.

It is used for testing thermal properties parameters such as coefficient of thermal expansion, thermal conductivity, and heat capacity of materials, as well as for quality analysis and purification of materials. It is an indispensable equipment.