M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

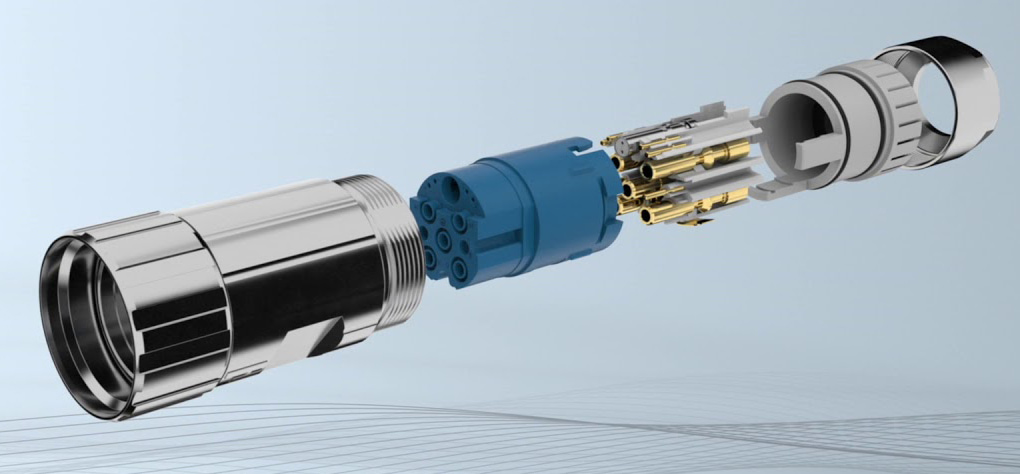

There are two types of M23 connectors, one is called M23 power connector, the other is called M23 signal connector. The most widely used M23 signal connectors are 12-pin and 17-pin, with 6-pin, 7-pin, 9-pin and 9+PE options also available. Different applications require different numbers of cores. M23 signal connectors are mainly used for signal and data transmission and require very good conductor material to ensure transmission speed and stability.

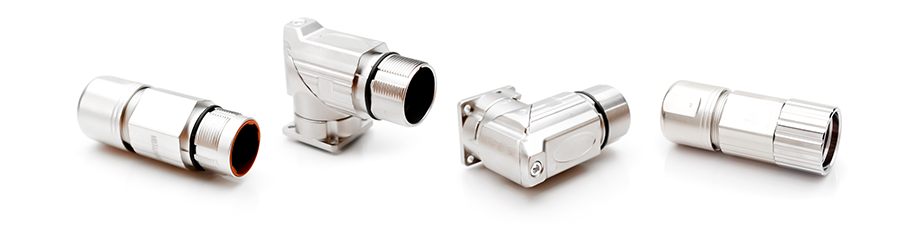

M23 signal connectors are available in male plugs, female plugs, male sockets and female sockets. The sockets are available in straight and angle types, 6 – 17 pin. Currently, the most used M23 signal connector sockets are front panel mounted, while the rear-mounted type is less. M23 connectors have excellent corrosion resistance. The shell is nickel plated brass, an assembly connector without complex tools, and easy and fast operation.

M23 power connectors are available in 6-pin and 8-pin. 6-pin is rated up to 630V and rated up to 30A. M23 power connectors are also modular in form. M23 power connectors have straight plugs and angled sockets for quick assembly or disassembly, which is conducive to field maintenance. The modular design of M23 connection signal and power connectors makes them flexible in function and expands their range of applications in industrial automation. The rugged housing and excellent protection suit harsh industrial environments, ensuring power and stable signal transmission.

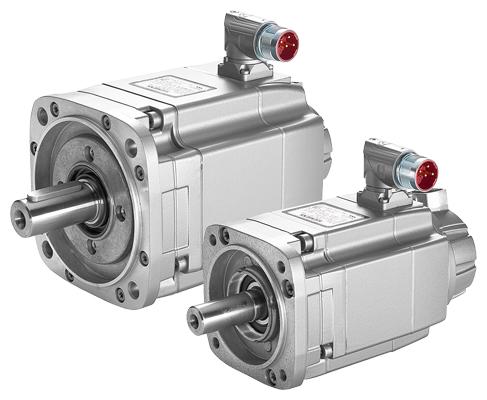

M23 circular connectors are mostly used in automation fields, such as motors, encoders, robots, etc. They are mainly used to solve complex transmission types and interference problems in industrial automation control. Signal transmission and power connection are their main applications. They have better protection performance than waterproof junction boxes and are easy to handle. M23 waterproof connector is an ideal connector solution for servo motors. While waterproof junction box to servo motor wiring still has a series of risks, such as low protection level, severe vibration, oil and corrosion environment failure, etc.

In the field of servo motors, size and space are important factors affecting the range of servo motor applications. As the connector is mostly mounted on the external interface of the servo motor, the height of the connector will directly affect the overall size of the servo motor. If the height of the connector is too high, the overall height of the servo motor will be too high. If the width of the connector is too wide, the small size of the servo motor cannot be installed. Servo motors are widely used in servo systems in automation fields, such as CNC punching machines, bending machines, shearing machines, PLC program controllers, all kinds of automotive testing equipment, assembly equipment, welding equipment, etc.

1.Excellent shock resistance. The unique anti-vibration locking mechanism prevents the connector from loosening, the surfaces of the contact parts of the connector are gold-plated, and their contact resistance is very low. The special design reduces the effect of vibration and the large contact surface between the male and female contacts ensures good electrical conductivity. The performance reliability, mating cycle, contact strength, contact resistance and other values are better than other connectors. Suitable for various complex environments such as high speed and high vibration.

2.Easy to assemble. This is an assembly-type connector with a classic design. The same housing can have different inserts and support different numbers of pins. The pin contact connects the conductors with a crimping tool that is easy to operate, with tight contact and superior conductivity. Very easy to assemble and disassemble for troubleshooting and field maintenance.

3.High level of protection: Superior product design, high-quality raw materials, nickel-plated brass housing, corrosion resistant and very rugged, core made of advanced polymer. The smooth surface protects against dust and contaminants, the cable is tightly connected to the connector housing. The high-quality waterproof rubber ring ensures excellent waterproof performance and protection up to IP67. It is especially suitable for harsh applications such as the food industry, marine-related projects, medical products, chemical industry, automation and other environments with corrosive gases, liquids, oil contamination, high temperature and humidity.

4.Excellent temperature resistance, suitable for the temperature range of -40℃~+125℃.

5.The contacts are crimped connectors, which makes the connectors have reliable connection performance. Good mechanical and electrical properties ensure the long-term stability of the connection, so it is very reliable.

6.360° shielding with good anti-electromagnetic interference capability.

Aviation plug M23 connectors are mostly used in harsher and more complex environments, such as the environment around seawater. This requires a special corrosion protection treatment for the housing of M23 connectors because the chlorine in seawater is very active and can erode the surface of many metals, causing severe corrosion. For example, galvanization and other performance treatments can be very good resistance to seawater and wind erosion to ensure the safety of the connection.

The aviation plug M23 connector should not be used beyond its operating temperature range. If used at too high a temperature, the properties of some plastic materials will change, affecting the connection’s reliability and protection. Working at very low temperatures also poses a risk that inconsistent shrinkage due to low temperatures may lead to cracking of the connector shell and affect the protection performance.

During the use of M23 connectors, it is necessary to follow operating instructions. For example, it is necessary to follow reasonable force during the tightening of the lock nut. Too much force can cause structural damage, and too little force can affect the waterproofing performance. Likewise, when crimping contacts, it is necessary to use the proper tool. The wrong tool can lead to poor crimping and contact deformation and poor electrical conductivity.

All electronic components, including M23 connector products, have a service life. If they work in an unsuitable environment, the service life will be greatly reduced and can cause unexpected product failure. As a frequently used waterproof connector, the application environment of the M23 connector should be evaluated to ensure that the conditions are within its capabilities and that it is well maintained in use.

When customers need to buy bulk M23 connectors, what factors need more attention from users? Here are some professional suggestions for purchasing.

The above details some knowledge about M23 connectors. Renhotec, as a professional connector manufacturer, has many years of experience in M series connectors. If you need to purchase M23 connectors, you can contact us directly, and our professional engineers will provide you with reliable solutions for free.