M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

The M12 connector is a common circular cable termination device. Widely used in industrial, mobile robotics, and even consumer-grade designs to connect detection, actuation, and other components (fieldbus, etc.) with the control and other systems of automated machinery.

The IEC 61076-2-101 standard of the International Electrotechnical Commission specifies the exact geometry and conductor arrangement for M12 connectors (usually located at both ends of a PUR jacketed or PVC jacketed cable). M12 gets its name from the metric threads (more on this later) on most connectors’ coupling nuts and mating jacks, which are basically 12 mm diameter M12 threaded fasteners.

Dozens of specialized options allow design engineers to specify products that are particularly suited to the machine or product design. The various device options include the following features:

The M12 connector was first released in 1982 as a non-standardized 7⁄8 inch three-pin connector for a small number of applications. The unique feature of this connector was its coupling nut (which in most cases still is) – the housing at the end of the cable locks axially at the end of the cable but can be freely rotated – and can therefore be screwed onto a matching male or female fastener on the jack side.

Firstly, the connector was standardized through the IEC 61076-2-101 standard for sensors and actuators. In subsequent years, the standard added a variety of M12 code definitions (detailing pin geometry and functional variations) and two smaller format devices for actuators and PLC(Programmable Logic Controller), switches, and I/O(Input/Output). These include the M8 connector (defined by IEC 61076-2-104 with an 8 mm fastener diameter) and the M5 connector ( defined by IEC 61076-2-105 with a 5 mm fastener diameter).

The latest version of IEC 61076-2-010 (2020) contains one of the most significant additions to the standard in quite some time – support and official definitions for push-pull connections. The cable companies involved in developing the standard include Molex, CONEC, Weidmüller, Phoenix Contact and HARTING. The main advantages of the push-pull M12 connector are:

How to significantly reduce installation time (no more tightening nuts and verifying the applied torque)

How to achieve a more compact connection than with conventional M12 connectors.

In fact, IEC 61076-2-010 2020 defines the geometry of both the internal locking sub-assembly on the female push-pull connector half and the external locking sub-assembly on the male push-pull connector half. This will ensure cross-compatibility between cable products.

Unlike the push-pull M12, another circular connector for communication and industrial HMI peripherals is available – the miniature DIN connector. Here, DIN stands for Deutsches Institut für Normung – the standard regulatory organization that specifies the internal construction and connection of these cable terminals. These connectors rely on an intervening fit (friction) between the cable end sleeves to hold the assembly after insertion into the socket.

This 9.5 mm (3/8 in.) mini-DIN connector features an array of 3, 4, 5, 6, 7, 8, or 9 electrical connector pins to prevent accidental misconnection with similar-looking mini-DIN cables. In many cases, suppliers add proprietary color codes to the end of the cable and to the receptacle on the machine side to help the assembler match up the two parts of the connection and make installation easier.

Both mini-DIN and mini M12 connectors have their own unique applications. However, there are more non-standard mini-DIN connectors on the market – although the design can be more liberal, it also creates confusion. In addition, the intervening fit of the mini-DIN fixing sleeve allows for quick connection and disconnection. In contrast, the screw connection of the M12 connector does take more time, but is inherently safer.

In addition to the pin count, the code version of the M12 connector is also more standard. Pin arrays, channels and recesses (to prevent incorrect mating) are specified, as well as the electromagnetic shielding design.

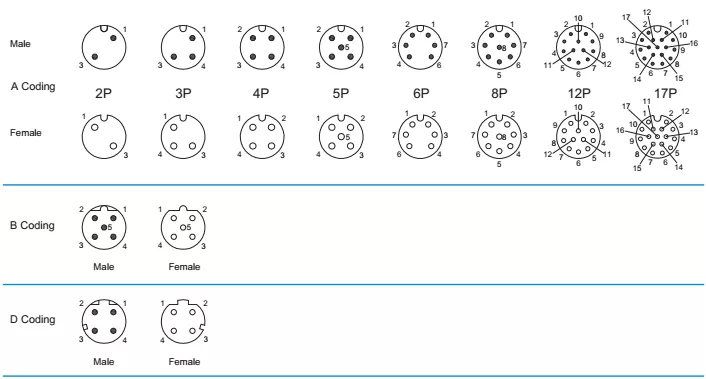

A Coded M12 connectors abound and are still used in network sensors and other small devices that rely on DC power. B Coded M12 connectors are common in PROFIBUS installations. C Coded double keyway (M12 power) connectors perform well in designs that require AC power for small automation components. D Coded M12 connectors support 100 Mb/sec Ethernet as well as PROFINET connections.

The newer M12 code versions include K-code and L-code connectors, supporting AC and DC power supplies respectively. Similar options are available for S-code connectors, which are capable of delivering up to 690V for running AC motors, and T-code M12 connectors for DC power.

However, there has been a dramatic rise in the use of X-coded M12 connectors to support 10Gb/s industrial Ethernet and to provide power to actuators such as stepper motors, taking advantage of the Ethernet 802.3at (PoE+) connectivity feature. The latter provides sufficient power to allow various actuators to operate at full power.

The days of hand twisting, insulating, and testing bare wires through cable ducts and taking hundreds of hours to install are over for automated machine wiring and physical networking. M12 connectors, along with other innovative wiring methods and a growing number of specialized cable sets, frequently eliminate the need for specialized installation while allowing for fast, safe, and trouble-free setup and easy replacement when necessary.

In fact, M12 connectors are part of the general trend toward simple, modular, and non-proprietary solutions for machine and factory automation.

Renhotec Group was established in May 2005, specializing in manufacturing and exporting various electronic connectors for over 15 years. You can get almost all commonly used connectors, adapters, cable assemblies from us at favorable ex-factory prices.

If you have needs for connector products, please click the button below to make an inquiry.