M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

The leap China’s high-speed rail has made from technology introduction to technology export has led the world in high-speed rail and successfully won global attention. With the development of high-speed rail technology, its data transmission has been showing steady growth. M12 circular connector plays an important role in this.

Ethernet is the most popular and mature network technology in the world today. It has the advantages of low price, high speed, easy networking, and easy connection to the Internet. It has benefits in high-speed data transmission and remote operation monitoring of trains.

Industrial Ethernet provides high bandwidth for many IP-based applications. Since the adoption of Ethernet to provide network access to the train’s PIS system (Passenger Information System), air conditioning system, contact network, traction brake, and other systems, the original CAN bus transmission method has been rapidly replaced.

Due to increasing passenger demands for comfort, Ethernet-based networks offer many subtle benefits to passengers in the rail infrastructure. The new generation of trains meets the needs of operators’ efficiency savings and new consumer loads. This includes first-class office equipment, entertainment, and passenger information. This has also led to increasingly complex applications in trackside areas and trains, placing greater demands on the reliability of data transmission.

In the face of increasing data transmission requirements, the complex application environment of railroads, and the trend of miniaturization of railroad connectors, circular connector M12 products continue to innovate. To ensure faster and more reliable communication in the ever-changing environment.

For high-speed rolling stock running at 300km/h or more, as the power source of the train, reliable pantograph contact is an important guarantee for the safe operation of the rolling stock. The key to the contact network monitoring system is transmitting pantograph contact status monitoring data at high speed, in real-time, safely, and stably. The traditional M12 data connector cannot meet such real-time requirements in terms of transmission rate and signal integrity.

The M12 CAT6A-X coding connector system is available in the field of connection technology. The innovative use of the X-shaped cross-shielding design. When mating, the connector plugs, and sockets are cross-shielded together, isolating each pair of twisted pair signals separately. Minimizes crosstalk and echoes from data transmission between pairs. It can provide up to 10G data transmission performance in the 500Mhz bandwidth, which is a significant advancement in circular connector data transmission.

At the same time, the M12 X-coded connector allows blind insertion. The embedded male pins prevent damage to the pins during mating. The robust construction and IP67 protection class ensure reliable dust and water resistance. Whether for the bow network monitoring system of high-speed trains or the rapidly developing in-car audio and video systems. M12 X-code connectors are undoubtedly the ideal choice for high-speed data transmission.

Space inside trains and railroad cars is at a limit. Therefore, the components must be compact enough to save space.

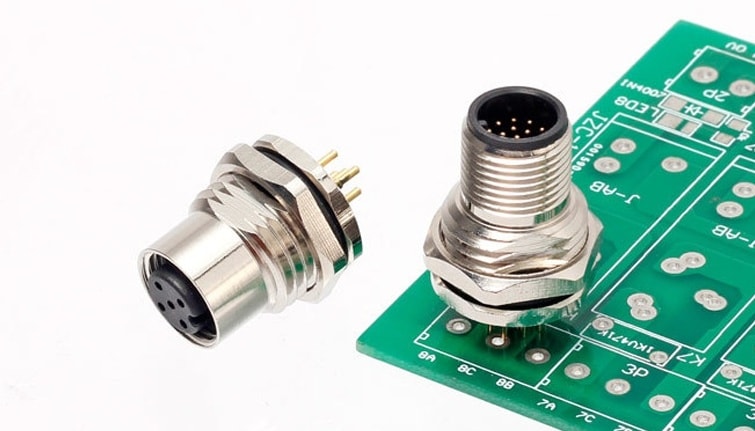

The M12 circular connector products are designed with a split structure, allowing users to easily choose between front-of-board, back-of-board, press-in, or tolerance-compensated fixed housings. The compact structure design allows for a flexible connector installation layout and space-saving.

At the same time, the plug side can choose IDC fast with no stripping technology, puncture connection, inline spring connection, and other innovative connection technology. Tool-free wiring method can maximize the user’s time to save on cable production.

M12 circular connector with SMT technology can fit on both sides of the PCB, and one PCB board can easily realize double rows of wires, especially suitable for railroad compact rack mounting. With automatic gripping, it can realize fully automated assembly line production.

Due to the vast area of China, the train operating area is extensive. The onboard equipment is usually placed in a narrow, harsh environment. So the connector must withstand the test of a long-term wet environment. In addition, the material fire resistance is also particularly important. The highest ambient temperature level, while the products are UL94-V0 flame retardant grade.