M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

M series connectors feature quick locking, easy installation, and reliable wiring, which brings more convenience to customers’ use.

Power distribution and signal transmission are common needs in industrial automation. The era of Industry 4.0 has brought another explosion of data communication. Designers of control devices and system solutions are closely focused on these three needs in their connector selection.

Network-to-network, network-to-PC, baseboard-to-baseboard, device-to-device, IC component-to-printed circuit board, and printed circuit board-to-printed circuit board connections are among the most common industrial connectors applications scenarios.

In addition to the diversity and complexity of application scenarios, designers and users have also plagued the harsh working environment. Humidity, dust, salt spray, corrosive gases, strong vibration, shock, frequent plugging and unplugging, electromagnetic compatibility, and other factors are interfering with the normal operation of the control system, but also the life of production equipment poses a hidden danger.

Renhotec offers the M5, M8, and M12 series of circular connectors by the IEC 61076 design standard. The number of pins covers 2 to 17, shielded and unshielded functions are available, and the protection level can reach IP67/68. The products are at the industry-leading level regarding structural design and electrical performance.

Renhotec circular connectors are thread-locked to improve their sealing and reliability. Different thread specifications are used for the same material to produce different threaded connections with different load-carrying capacities.

The contact force per turn of the screwed thread is analyzed for M5, M8, and M12 thread sizes. It provides a new solution to determine the number of turns in the connector design. It improves the vibration resistance of circular connectors.

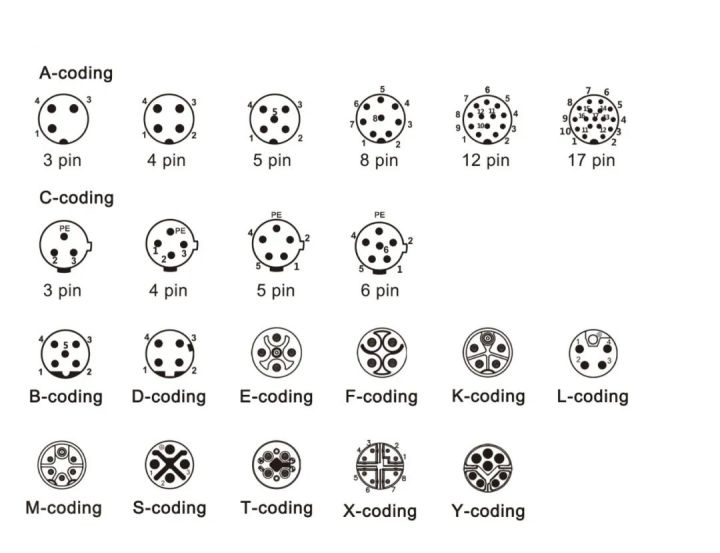

In the operation process, operators sometimes make mistakes due to misinsertion or blind insertion. By incorporating error-proof coding into the product, installation errors can be effectively avoided.

Modern industrial production environments and industrial automation sites are complex. Intrusive materials such as water droplets, metal chips, and dust can directly threaten the power distribution system. Most of the fault points are located at the cable connections. Connectors that are not dustproof and waterproof are susceptible to short circuit tripping caused by intruders.

IEC60529 standard has been widely adopted by the industry as a common connector waterproof, dustproof standard. The standard provides dustproof levels 0 ~ 6 and waterproof levels 0 ~ 9. The actual situation can be compared with the IP protection level of the site to choose the appropriate standard connector.

| IP degree of protection against contact and intrusion of foreign objects | ||

|---|---|---|

| Protection against contact | Prevent foreign body intrusion | |

| 0 | No protection | No protection |

| 1 | Any larger surface of the body (such as the back of the hand) | Large foreign objects (diameter >50㎜) |

| 2 | Fingers | Medium-sized foreign body (diameter>12㎜) |

| 3 | Tools and wires (diameter > 2.5㎜) | Small foreign body (diameter>2.5㎜) |

| 4 | Tools and wires (diameter > 1.0㎜) | Granular foreign matter (diameter>1.2㎜) |

| 5 | Complete prevention of contact | Dust accumulation |

| 6 | Complete prevention of contact | Dust intrusion |

| IP rating against water intrusion | |

|---|---|

| Prevent water intrusion | |

| 0 | No protection |

| 1 | Prevent vertical water entry |

| 2 | Protection against the influence of vertically (up to 15°) falling water droplets |

| 3 | Prevent the influence of water spray 60° away from the vertical direction |

| 4 | Protection against water droplets splashing from any direction |

| 5 | Water column to prevent spray (10L/min) |

| 6 | Prevent strong water column (100L/min) |

| 7 | Prevent temporary immersion in water (30min, 1m) |

| 8 | Prevent prolonged immersion in water (>30min, 1m) |

| 9 | Prevent downward high pressure, high temperature jet (80 ℃) |

The correct choice of material is the basic guarantee of the electrical and mechanical properties of the connector. Renhotec for the M series housing material can be selected according to the customer’s use of the environment. The plastic material can withstand machine operation at -25 to 85 degrees Celsius.

Most of the insulated housings are injected with molded liquid crystal polymer PA or PU, which has good overall performance. Including mechanical properties, heat resistance, and wear resistance, these insulating materials have higher retention and good electrical insulation strength.

M series circular connectors are widely used in robotics, industrial automation, CNC equipment, textile machinery, rail transportation, monitoring equipment, energy communication, and other applications that require power, data, and signal connections. In addition, our strong customization service capability also provides more options for customers’ diversified needs.