M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

Circular M12 and M8 connectors are ideally suitable for these highly demanding applications. They are an excellent choice for harsh environment applications with high-speed data transmission.

Water, dust, and mud affect vehicle and equipment electronics in agriculture and other outdoor operating environments.

Modern industries characterized by outdoor facilities and equipment rely on resilient and reliable electronic connections. Promote good communication between equipment and operators in harsh environments. Industries such as agriculture, food and beverage processing, transportation, and energy have advanced equipment that must operate successfully in challenging environments.

In this environment, vehicles and equipment exposed to changing weather conditions have the potential to enter a variety of contaminants, including water, dust, chemicals, and debris.

These electronic connectors must be able to prevent the ingress of contaminants and withstand extreme temperature, shock and vibration, and pressure conditions; while providing reliable signal transmission. All of this must be done within a limited space, and the connectors must be highly reliable.

ERNI modular M8 and M12 circular connectors are available with various codes and accessories, including protective caps and O-ring seals, for almost all Fieldbus specifications.

M12 connectors have long provided reliable signal transmission for the home and office. With automation and increasing connectivity, the introduction of Industry 4.0, Industrial Ethernet, and more has created new demands.

The D-encoded M12 product is capable of 100Mb/s Ethernet transmission speeds. The X-encoded M12 product now replaces it with an Ethernet transfer rate that can reach 1GB/s. The X-coded M12 connector is better suitable for factory noise, process demands, and harsher environments in manufacturing environments.

It is better able to respond to data processing on the factory floor. In addition to manufacturing, X-code M12 connectors are available for agricultural equipment, public transportation, railroad infrastructure, and broadcast systems.

Industrial activities are not limited to the scope of manufacturing; they also include vehicles and facilities in remote locations such as agriculture, forestry, and energy sites. Equipment in this field uses sensors to provide data about conditions such as time, temperature, pressure, moisture, and vibration.

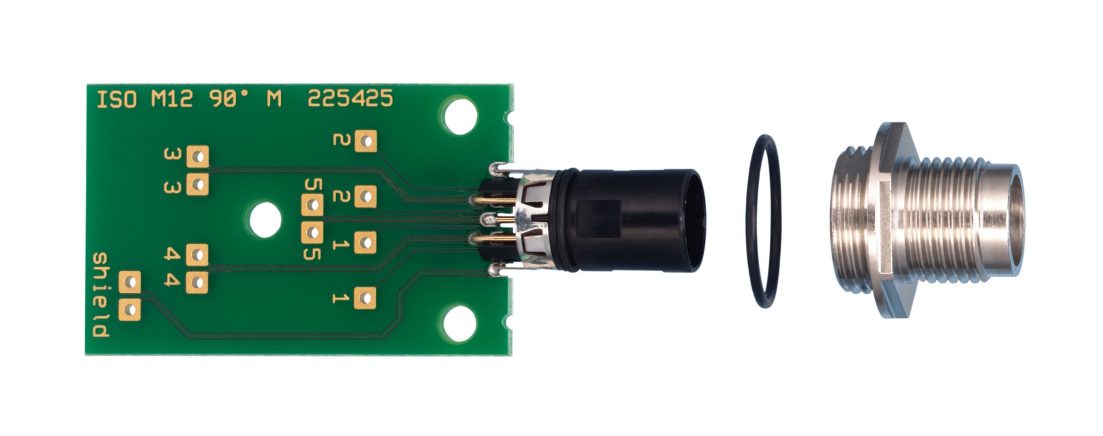

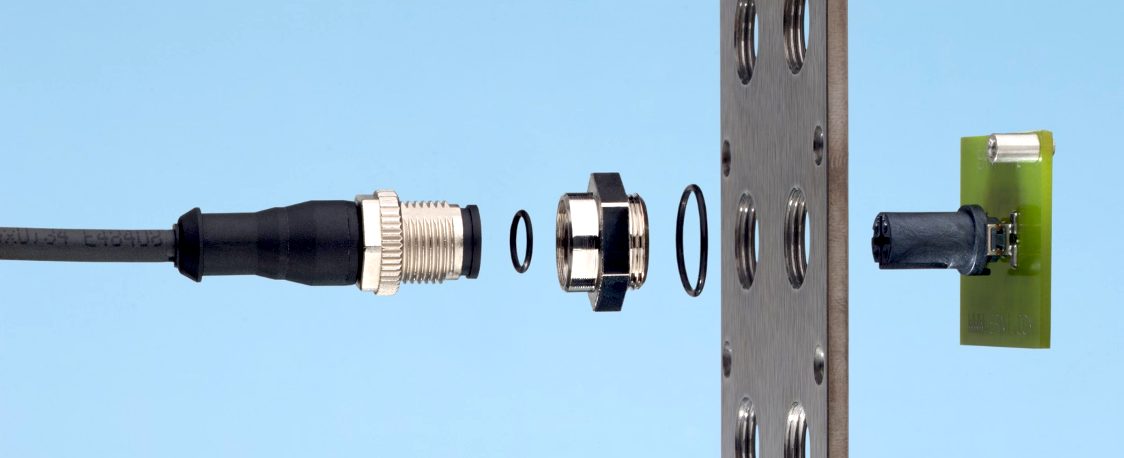

The angled M12 connector with 600 comparative tracking index (CTI) is fully insulation and can match sensors and other components in these harsh environment applications. Engineers can also choose to add shielding and O-rings to achieve an IP65/67 M12 connector solution. When these connectors are mated and locked, they reliably transmit signals under harsh environmental conditions.

ERNI M12 right-angle connectors

Agricultural vehicle connectors must be designed to prevent the ingress of water, dust, sand, etc.; and operate under harsh conditions such as extreme temperatures, vibration, and high-pressure washdown; while providing reliable signal transmission.

M12 and M8 connectors are available in various models with IP ratings from IP67 to IP69K, pin counts, shielding, termination, and coding. These solutions will meet a wide range of environmental conditions. At the same time, providing a high-quality signal to the on-board or remote operator.

Since its market introduction in the mid-1980s, the M12 connector has continued to evolve to meet the changing needs of vehicles and equipment operating in harsh environments. As vehicles become part of the Internet of Things, they increasingly demand highly reliable connectivity.

Agriculture and its transportation markets are becoming more high-tech. M12 connectors are one of the ideal choices. They are easy to install and modify, making M12 and M8 connectors an effective solution for harsh environment signaling applications.