M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

The M12 connector is a circular connector with a 12-mm locking thread that is used primarily in factory automation applications for actuators, sensors, industrial ethernet, and Fieldbus. M12 connectors are designed for washdown and corrosive environments. They are available with 3, 4, 5, 6, 8, and 12 pins.

Yes, M12 connector is waterproof when properly assembled.

M12 connector is IP67 rated. 6 means completely dustproof and 7 means protected against temporary immersion in water.

A metal threaded coupling nut provides a strong, tight connection that protects the connector interface from external elements such as water and dust. An interface gasket or O-ring is used to form a watertight seal between the plug and socket. When fully tightened, the connector fitting exerts pressure on the gasket, preventing water and moisture from entering.

The two connector halves must be IP67 rated in order to be paired for a watertight connection. The cable must also be suitable.

IP67 has been tested to withstand immersion in water from 15 centimeters to 1 meter deep. However, it is not suitable for prolonged underwater use. The waterproof rating only applies when the connectors are mated. Unused connector halves that are not covered may allow water to enter.

So, in summary, properly assembled M12 connectors are reliably waterproof, washdown and temporary immersion proof in industrial environments. However, M12 connector is limited by their IP rating and are not suitable for deep and permanent immersion.

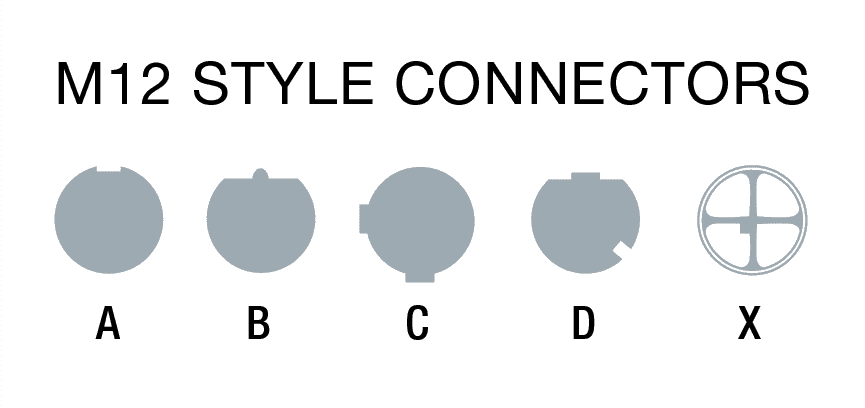

First, M12 A-coded connectors are widely used and have been around for decades. They’re also the most versatile in terms of the types of connections they support, as well as the number of pins housed in the connector (between three and 12 or even more). They support direct current (DC) connections and are used to connect sensors and actuators, as well as Ethernet connections up to Category 5e (four-pair connections).

M12 B-coded connectors are for network or non-Ethernet fieldbus connections (the most common is PROFIBUS). They can be used for sensor connections as well. Over time, we may see fewer of these connectors in use as PROFIBUS and similar fieldbus protocols are replaced with Ethernet.

M12 D-coded connectors are used primarily for industrial Ethernet connections, such as PROFINET and EtherNet/IP. They provide a form factor that supports two-pair connections. Unlike M12 X-coded connector, D-code doesn’t support Gigabit Ethernet; it only supports Fast Ethernet (100 Mb/s).

Lastly, M12 X-coded connectors are a more recent development designed specifically to support Gigabit Ethernet. In addition to preventing mis-mating, these connectors are designed with walls between each group of two pins (four groups of two pins overall). The walls prevent crosstalk and interference to achieve excellent Category 6 or 6A performance (up to 10 Gb/s).

It is well known that RJ45 plug connectors are the most commonly used connection technology for Ethernet systems, but for Ethernet networks deployed in harsh outdoor or industrial environments, M12 plug connectors are often a better choice for many applications.

Impurities such as dirt, dust, metal shavings or other foreign particles can accumulate on the mating surfaces of the connector. When mating, these contaminants may be trapped between the pins or sockets, resulting in poor electrical contact or even a short circuit.

To minimize debris interference:

M12 connector is designed to provide a degree of protection against moisture and are typically rated IP67 or better. However, under extreme conditions, moisture can still enter the connector and may cause electrical problems or corrosion.

To minimize moisture interference:

When using M12 connectors, it’s important to refer to the manufacturer’s documentation and guidelines for the specific type of connector you are working with to ensure proper installation and performance.

If you have any needs for our company’s products, please contact us by phone or email:

Mobil:(+86)18086610187

Email: [email protected]