M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

The M12 connector, as a metric circular connector, plays a vital role in industrial automation and other challenging environmental applications. Widely employed in the industrial market, these connectors hold particular significance in supporting Industrial Internet of Things (IIoT) system connections.

M12 connector is part of the M5 to M12 series of electrical connectors with metric thread sizes. The external thread diameter is used to identify different specifications. Manufacturers consider M12 connectors that comply with the IEC-61076-2-101 standard as universal products, offering multiple locking mechanisms and other options. According to the standard, M12 connectors with the same coding can be interchanged and are backward compatible, enabling them to work with M12 interfaces of the same coding produced by other manufacturers. Furthermore, M12 connectors can meet bandwidth requirements of up to 10 Gb/s, support a power supply voltage of 16 V, and can be configured to support protocols like Profinet, SPE, and fieldbuses.

The history of M12 connectors dates back to 1985 when the German connector company Lumberg introduced the M8/M12 connector interface at the Hanover Industrial Fair. Initially designed as waterproof alternatives for RK30 sensor connectors, they gradually became a common choice in automotive manufacturing facilities at the time.

The M12 connector utilizes the IEC 61076-2-101:2012 standard.

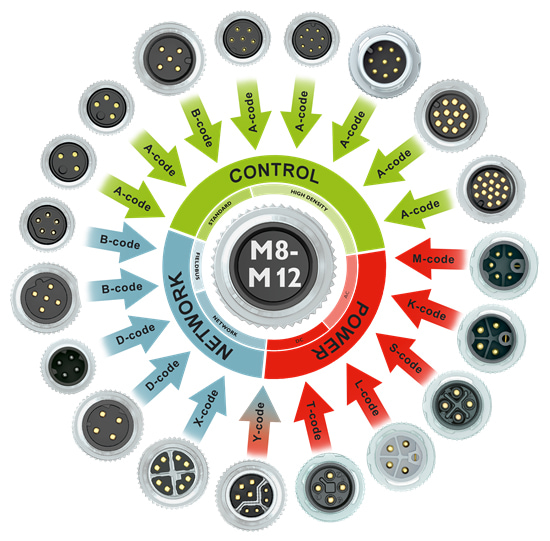

Ensuring proper mating and to prevent mismatches, the M series circular connectors offer specific coding options that define the pin count and arrangement:

People typically use M12 connectors with Cat5E and Cat6A cable types.

Up to 16V

The M12 is available in a variety of mounting options, including through-hole mounting, surface mount, and wave soldering.

Metals used in the M12 housing include stainless steel, brass, copper, gold and alloys.

Manufacturers carefully consider M12 connectors and cable assemblies to ensure stable operation in harsh environments, such as extreme temperatures, radiation, rough handling, and chemicals.

M12 connectors are available in IP67, IP68, and IP69 models to ensure protection from fluids and particles in harsh operating environments. Waterproofing and sealing features are especially important in scenarios involving fluid and pneumatic configurations.

Electromagnetic Interference (EMI) or Radio Frequency Interference (RFI) is a significant issue in environments filled with electronic devices. M12 connectors offer shielded and unshielded connector and cable assembly options to effectively minimize interference.

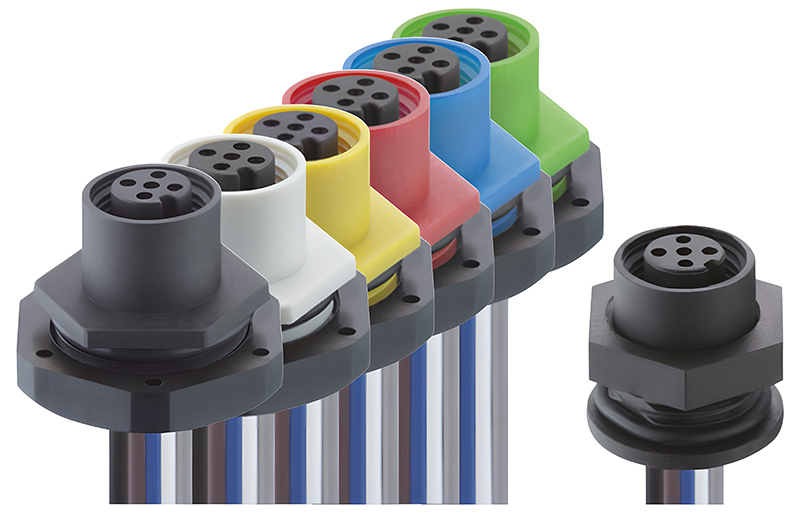

M12 connectors are designed to provide fast, easy connections, even under challenging conditions. They are available in screw, bayonet and ergonomic push-pull locking mechanisms for blind mating situations. Keyed, color-coded and LED options are available to enhance connection reliability. In addition, M12 connectors are field repairable and backward compatible, simplifying the maintenance and upgrade process.

Like this article? Check out our other “How to choose M12 connectors“, “M12 connectors in industrial automation” and “Difference between M8 and M12“. Follow us on LinkedIn and Facebook for more applicable, specialized connectivity content.