M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

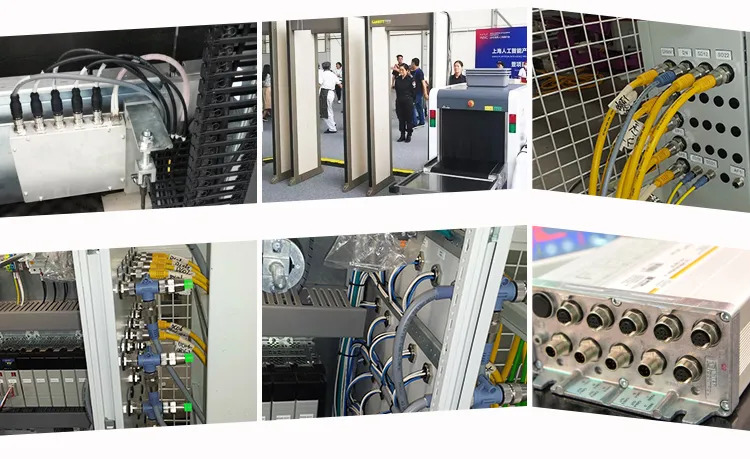

M12 connector is an electronic connector with a round appearance, usually used to connect sensors, actuators, automation equipment, robots and other equipment and systems in industrial automation. In industrial automation, M12 connectors have become a widespread connector because of its small size, high reliability and reliable protection performance, which can adapt to the requirements of harsh production environments and high-speed movement of equipment. It can transmit power and signals and has a wide range of applications in industrial automation.

Shape and structure: M12 connectors have a round shape with 3, 4, 5, 6 and 8 pins. It is usually divided into two types of male and female heads connecting different devices. It is compact and easy to install and use.

Material: M12 connectors are usually made of metal or plastic. Metal materials have higher durability and protection, while plastic materials are easier to install and use.

Durability: M12 connectors can withstand high frequency of connection and disconnection with high mechanical strength and durability. It can be used in harsh environments, such as high temperature, low temperature, high humidity, dust, etc.

Protection level: M12 connectors usually have different protection levels and can reach IP67 or even IP68 levels of protection. This makes maintaining a reliable connection and working conditions in harsh environments possible.

Electrical performance: M12 connectors usually have high electrical performance and can transmit high frequency, high speed, high voltage and high current signals. It can also transmit safety signals and data, making it widely used in modern industrial automation.

1. Robotics

Robotics is an essential part of the industrial automation field. Robots must usually connect to control systems, sensors and other devices to automate production. m12 connectors can easily connect various devices and methods of robots, thus improving the repeatability and reliability of the robot. Robot manufacturers can use M12 connectors to provide their customers better installation and maintenance support while increasing productivity.

2. Sensors

In industrial automation, sensors are essential for detecting and controlling various processes. While traditional sensor connections require special cables and adapters, M12 connectors can quickly solve these problems, thus improving the reliability and repeatability of sensor connections. With M12 connectors, sensor manufacturers can soon provide their customers with faster installation and maintenance support while increasing productivity.

3. PLC

PLCs (Programmable Logic Controllers) are another essential component of industrial automation, and PLCs are often connected to various devices and systems, including sensors, robots, and other equipment. Using M12 connectors, PLC manufacturers can quickly provide their customers with faster installation and maintenance support while increasing productivity. In addition, because the M12 connector is standardized, different PLCs can be easily connected, enhancing the scalability and flexibility of the overall system.

1. Easy to install: M12 connectors can connect devices quickly and accurately, making them easy to install, maintain and replace.

2. High reliability: M12 connectors are highly reliable due to their compact external structure and well-protected internal design, which is resistant to harsh environments.

3. Anti-interference: M12 connectors are made of high-quality materials and design, which can effectively suppress external interference and electromagnetic interference.

4. Good compatibility: M12 connectors have standardized pins, which are easy to use and apply, so they are widely used in industrial automation systems.

5. High protection: Adapt to use in harsh environments

Although M12 connectors have a wide range of applications in industrial automation, it also faces many challenges and problems. The following is an analysis of some common challenges and difficulties faced by M12 connector.

1. Insufficient Standardization

Although the M12 connector is a standardized connector, in industrial automation, different devices and systems are very much between the connector specifications and types, making the connector standardization relatively low. This will bring some difficulties to the integration and maintenance of the system and also increase the equipment cost.

2. Compatibility Issues

Due to the relatively low standardization of M12 connector, the compatibility of the connector may be affected between different devices, systems and brands. This may lead to unstable device connections and jeopardize the reliability and stability of the system.

3. Reliability Issues

Although the M12 connector is reliable, in practical applications, the reliability of the connector may be reduced due to environmental, temperature, vibration and other factors. This may lead to an increase in the connector’s failure rate, affecting the system’s operational efficiency and stability.

4. Security Issues

In the field of industrial automation, safety is essential. Although the M12 connector is safe, in some special applications, such as high voltage, high temperature and other environments, the connector’s safety may be affected, thus posing a security risk.

In summary, M12 connectors face some challenges and problems in industrial automation. In the future, with the continuous development of technology and the expansion of application areas, M12 connectors need to continue to improve and innovate to meet these challenges and problems and improve the system’s reliability, stability and safety.

M12 connectors play an important role in connection technology in the field of industrial automation, and the innovations they bring are mainly in the following areas:

In the future, M12 connector in industrial automation applications and development prospects remain extensive:

Further expansion of application areas: M12 connectors are particularly suitable for small, high-density connection needs. With the continued renewal and upgrading of automation equipment, the application of M12 connector will be further expanded.

Continuously improve the connection bandwidth and speed: To meet the increasing demand for data transmission in industrial automation, M12 connectors need to improve their connection bandwidth and transmission speed to complete the connection needs of more advanced, miniaturized automation equipment.

Strengthen to meet the requirements of environmental protection and energy saving: In the context of global environmental awareness continues to rise, M12 connector will gradually develop in the direction of more environmentally friendly and energy-saving requirements.

Continuously improve the integration of the connector: in size, material and other aspects of continuous optimization. In the future, M12 connectors will become increasingly compact and lightweight and gradually realize the intelligence of the interconnection.

Overall, the future application and development prospects of M12 connectors are extensive. With the continuous improvement of technology and the growing market demand, it has a vast market potential and development space.