M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

Although M12 connectors have been widely used in industry for decades, its innovation and changes are advancing as new connected industrial technologies continue to innovate.

Something has widely used M12 connectors for decades long before the Industrial Internet of Things (IIoT) or Industry 4.0. More recently, they have become the connector of choice for industrial Ethernet. As industrial environments become increasingly interconnected, designers and OEMs are integrating M12 connectors into new machines. They are also using these connectors to update existing infrastructure. Compared to other older or less robust connectors, the M12 series offers better compatibility, lower cost of use, and higher benefits.

On the device side, we can use M12 connectors for data transfer, extracting data from the device and transferring it to the application center. The M12 connectors also connect programmable logic controllers (PLCs), sensors, input/output (I/O) modules and wireless access points (WAPs), among others. M12 connectors have long been used in a wide range of low-voltage power sources, such as alternating current (AC) motors and drives, motor control switches, and field bus Ethernet components and network devices.

As interconnect applications now change, M12 connector technology continues to evolve. New features are being added to M12 connectors to meet the needs of various industries such as robotics, automation, food and beverage, alternative energy, transportation, and cellular communications. These versatile, rugged and flexible custom connectors make them ideal for industrial environments.

M12 connectors are available in a variety of configurations, giving designers more options for foot placement, locking and coding characteristics, etc.

At the factory or application site, the user must be able to disconnect the connector for maintenance or replacement and quickly install a new connector, especially in applications that must be waterproof or dustproof. M12 connectors are easy to install and have clear coding that reduces the possibility of accidental mating errors.

As applications require higher speed connections, X-coded connectors, such as these Renhotec’s M12 X-coded female chassis connectors.

M12 codes for signal and data transmission:

M12 codes for power supplies:

S-Coded and K-Coded connectors for AC power supplies up to 630V/16A. Ideal power connectors for applications such as AC motors and drives, motor control switches, and frequency inverters.

T-Coded and L-Coded connectors for DC power supplies up to 63V DC/16A. Power connectors for low-voltage applications such as DC motors and drives, fieldbus Ethernet components, network devices and LED lighting fixtures

M12 connectors are available in pin count options of 3, 4, 5, 8 or 12. The ideal number of PINs depends on the application. For example, most sensor and power applications use three to four PINs, while PROFINET and Ethernet use 4 and 8 PINs, and 12 PINs are used for signal transmission applications.

There are three basic types of coupling systems for M12 connectors:

1.Push-pull: Easy to fit, with an audible “click” sound to indicate a successful connection.

2.Threaded: Highly resistant to vibration.

3.Bayonet: uses pins in the socket and can be tilted on the plug for a quick fit.

Application-specific connectors or cable assemblies can be customized by selecting specific options, including:

M12 connectors are ideal for industrial environment applications because they provide excellent performance in harsh environments. This is because M12 connectors offer IP67 rated environmental protection against dust and water, while also resisting adverse factors such as shock, vibration, UV exposure, and temperature cycling. For more demanding applications, such as those requiring frequent cleaning, M12 connectors are also available with IP68 and IP69K ratings for hermetic protection.

In addition, mating cycle ratings are an important factor that manufacturers must consider when selecting connectors. Connector mating cycles depend on the performance of the contact and plating materials used, as well as the plating thickness. Gold-plated beryllium copper contacts made from corrosion-resistant materials typically have mating cycle ratings in excess of 100 cycles compared to the use of low-cost tinned copper alloy contacts. Therefore, manufacturers need to consider not only the cost but also the mating cycle rating of the connector when selecting a connector. Such as Binder M12 A coded connector.

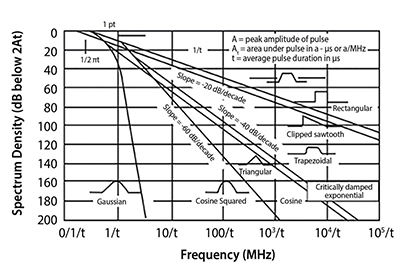

Hardwired M12 connections have additional advantages over wireless connections, including the inherent security of the physical connection and protection from interference, which is especially critical in IIoT factories that are full of electromagnetic interference (EMI), such as radio frequency interference (RFI). This electronic noise pollution often interferes with high-precision sensors that are in the harsh environment of physical noise and vibration in busy factories.

In addition to the necessity of high signal integrity requirements, Industry 4.0 applications also require more compact components and connection solutions, with the same need for increased power and data transfer capabilities. As smaller and smaller devices and sensors need to transmit more data, more connection points become imperative and connectors must carry high power density but still remain small in size.

Originally designed to reduce the size of standard connectors, the M12 connector has a diameter of only 12 mm. This small size makes the M12 connector suitable for applications where space is extremely limited, such as automation control systems, telemetry modules, compact LED lighting fixtures, and actuators.

Not only can M12 connectors transmit data and power in harsh industrial environments, but they also have several key features such as ruggedness, interference resistance and flexibility. Therefore, as Industry 4.0 applications continue to develop and mature, M12 connectors will be indispensable as a key component.