M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

Mil-C-5015 series connectors conform to US Harsh Environment Connectors Mil-C-5015 standard (GJB600), with high strength Aluminum Alloy shell, Synthetic rubber insulator, threaded coupling, Alternate insert positioning, solder and crimping terminal, low cost, simple and practical design, widely used in industrial machinery and equipment, Harsh Environment Connectors, defense equipment, marine, automobile industry, instrument, and servo motor, etc. Our connectors can replace European and American similar products.

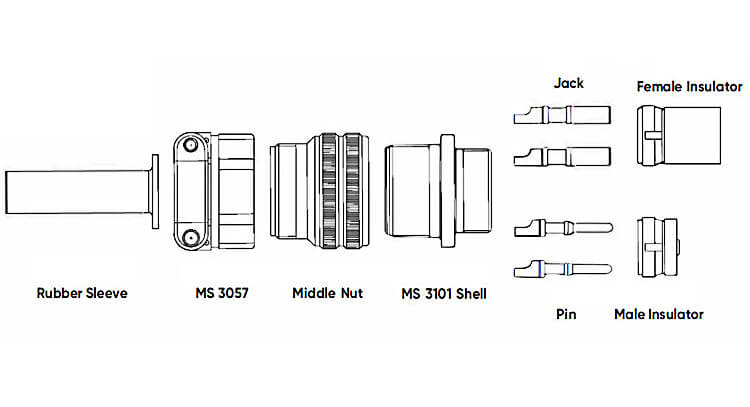

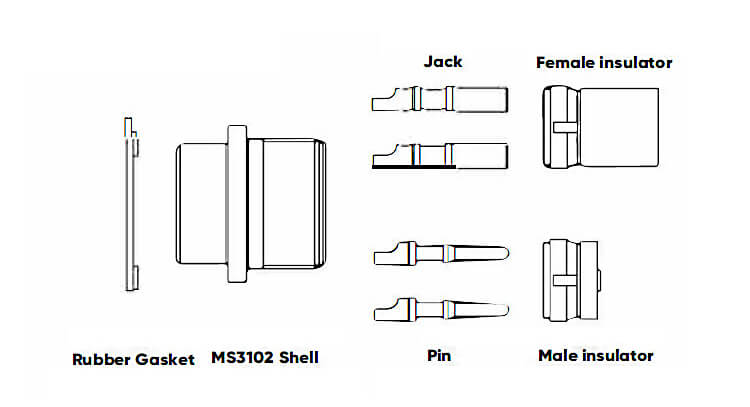

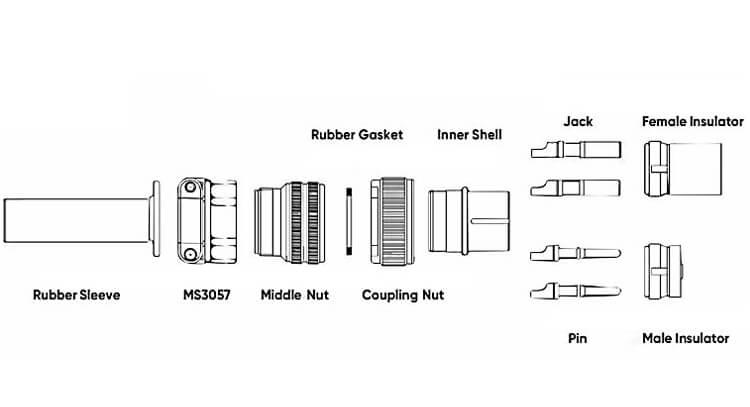

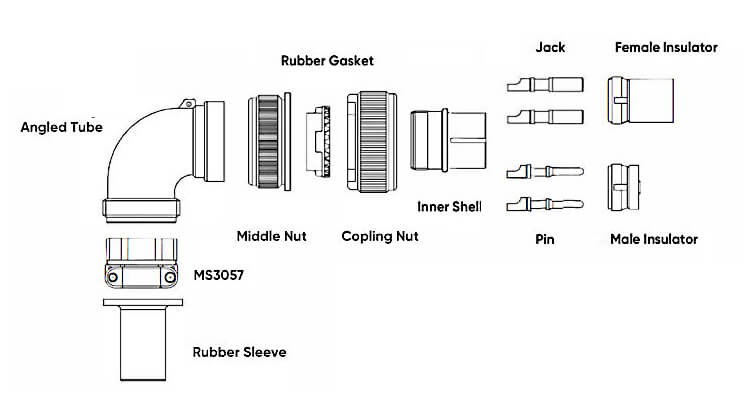

The MS5015 series connectors are available in various plug and receptacle styles, including MS3100, MS3101, MS3102, MS3106, and MS3108.

MIL-C-5015, characterized by its threaded coupling, single key, and keyway polarization, embodies simplicity in design. They find extensive use in industrial machinery, defense ground support equipment, munitions, and maritime installations. The MIL-C-5015 connectors come in classes A, B, E/F, R, and also provide a variety of pre-earth connectors. Hence, Renhotec is your go-to place for finding the perfect connector that meets your specific conditions and performance requirements.

MIL-DTL-5015 is a United States Mil Standard which covers heavy-duty circular electrical connectors with soldered or crimped contacts. Defense, aerospace, and industrial machinery commonly use them for both digital and analog signals, as well as power distribution.

MIL-DTL-5015 connectors are IP67 rated for high-performance in critical applications. Aerospace-grade aluminum shells provide heavy-duty protection while a standard olive drab cadmium finish provides excellent corrosion resistance.

Series 1: bayonet coupling mechanism with scoop-proof design.

Series 2: bayonet coupling with a low-profile design to meet weight and space restrictions.

Series 3: self-locking threaded coupling mechanism.

Series 4: breech-lock coupling mechanism.

MS5015 connectors are anti-knock, damp proof, flame-retarded, anti-corrosion, heat-resistant and dust-proof. Apply to industrial medical aviation and other major fields.

| Connector Type | |||

|---|---|---|---|

| Fastening Type | |||

| Number of Positions | 1-64Pin |

||

| Connection Type | Cable Plug, Panel Mount Receptacles |

||

| Orientation | |||

| Shell Material | Aluminum Alloy |

||

| Shell Finish | Olive Drab Cadmium |

||

| Insulation Material | Synthetic Rubber |

||

| Wire Gauge | 20-12AWG |

||

| Connector Type | Fastening Type | ||

| Number of Positions | 1-64Pin |

Connection Type | Cable Plug, Panel Mount Receptacles |

| Orientation | Shell Material | Aluminum Alloy |

|

| Shell Finish | Olive Drab Cadmium |

Insulation Material | Synthetic Rubber |

| Wire Gauge | 20-12AWG |

| Contact Type | |||

|---|---|---|---|

| Contact Termination | Solder Cup |

||

| Contact Material | Copper Alloy |

||

| Contact Type | Contact Termination | Solder Cup |

|

| Contact Material | Copper Alloy |

| MPN | CA3100A20-18P, CA3101A20-18P, CA3101A20-18S, CA3102A20-18P, CA3102A20-18S, CA3106A20-18P, CA3106A20-18S, CA3108A20-18P, CA3108A20-18S, MS3100A20-18P, MS3100A20-18S, MS3101A20-18P, MS3101A20-18S, MS3102A20-18P, MS3102A20-18S, MS3106A20-18P, MS3106A20-18S, MS3108A20-18P, MS3108A20-18S |

||

|---|---|---|---|

| Key | N |

||

| MPN | CA3100A20-18P, CA3101A20-18P, CA3101A20-18S, CA3102A20-18P, CA3102A20-18S, CA3106A20-18P, CA3106A20-18S, CA3108A20-18P, CA3108A20-18S, MS3100A20-18P, MS3100A20-18S, MS3101A20-18P, MS3101A20-18S, MS3102A20-18P, MS3102A20-18S, MS3106A20-18P, MS3106A20-18S, MS3108A20-18P, MS3108A20-18S |

Key | N |

| Rated Current | 15A, 30A |

||

|---|---|---|---|

| Rated Voltage | 500V |

||

| Insulation Resistance | 5,000 Mega ohms minimum (at 25°C) |

||

| Rated Current | 15A, 30A |

Rated Voltage | 500V |

| Insulation Resistance | 5,000 Mega ohms minimum (at 25°C) |

| Mechanical Operation | >500 Mating Cycles |

|---|---|

| Mechanical Operation | >500 Mating Cycles |

| Connector Type | |

|---|---|

| Contact Type | |

| Fastening Type | |

| MPN | CA3100A20-18P, CA3101A20-18P, CA3101A20-18S, CA3102A20-18P, CA3102A20-18S, CA3106A20-18P, CA3106A20-18S, CA3108A20-18P, CA3108A20-18S, MS3100A20-18P, MS3100A20-18S, MS3101A20-18P, MS3101A20-18S, MS3102A20-18P, MS3102A20-18S, MS3106A20-18P, MS3106A20-18S, MS3108A20-18P, MS3108A20-18S |

| Number of Positions | 1-64Pin |

| Connection Type | Cable Plug, Panel Mount Receptacles |

| Orientation | |

| Contact Termination | Solder Cup |

| Key | N |

| Shell Material | Aluminum Alloy |

| Shell Finish | Olive Drab Cadmium |

| Insulation Material | Synthetic Rubber |

| Contact Material | Copper Alloy |

| Rated Current | 15A, 30A |

| Rated Voltage | 500V |

| Insulation Resistance | 5,000 Mega ohms minimum (at 25°C) |

| Mechanical Operation | >500 Mating Cycles |

| Wire Gauge | 20-12AWG |

| Operating Temperature | -55°C ~ + 125°C |

| Ingress Protection |

We look forward to hearing from you! We will respond within 24 hours.

HW49+FG Xinhui District, Jiangmen, Guangdong Province, China

[email protected]

0086-769-81100186

0086-18086610187 (7d/24h online)

Mon - Fri 8:30 - 18:00