M Series Connectors

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

This article mainly introduces the composition and role of high-voltage systems in new energy electric vehicles

The composition of the high-pressure system

In the new energy electric vehicle, the parts with high voltage of the whole vehicle include power battery, drive motor, high-voltage distribution box (PDU), electric compressor, DC/DC, OBC, PTC, high-voltage wiring harness, etc., these components It forms the high-voltage system of the whole vehicle, in which the power battery, the drive motor, and the high-voltage control system are the three major components of the new energy electric vehicle.

1.Battery pack and power battery management system BMS

Different from traditional fuel vehicles, the power source of new energy electric vehicles is the power battery, not the engine. Because pure electric vehicles use electric energy directly, they do not need to burn the fuel and discharge the emissions into the atmosphere like traditional fuel vehicles. Therefore, in order to reduce environmental pollution, the development of new energy vehicles is actively supported by the state.

The voltage of the new energy power battery is generally 100~400V, and its output current can reach 300A. The capacity of the new energy power battery directly affects the mileage of the vehicle, and also directly affects the charging time and charging efficiency. Lithium-ion power batteries are currently the mainstream. Affected by current technology, most current cars use lithium-ion power batteries.

2.Drive motor and motor controller MCU

The motor controller MCU converts high-voltage direct current to alternating current, and performs signal interaction with other modules on the vehicle to achieve effective control of the drive motor. The drive motor converts electrical energy into mechanical energy to drive the car. Unlike traditional fuel vehicles, which convert the chemical energy of fuel combustion into mechanical energy, the engine has a higher working efficiency, which can reach more than 85%. Therefore, compared with traditional vehicles, its energy utilization rate is higher and can reduce the waste of resources.

3.High voltage distribution box

The high-voltage power distribution box is a power distribution device for the high-voltage power of the entire vehicle, similar to the electrical fuse box in the low-voltage circuit system. The high-voltage fuse box PDU (Power Distribution Unit) is composed of many high-voltage relays and high-voltage fuses. There are related chips inside it to realize signal communication with related modules to ensure the safety of high-voltage electricity for the whole vehicle.

4.Car charger OBC

On Board Charge is a device that converts alternating current to direct current. Because the battery pack is a high-voltage direct current power supply, when using alternating current for charging, the alternating current cannot be directly stored by the battery pack. Therefore, an OBC device is required to convert the high-voltage alternating current to high-voltage direct current to charge the power battery.

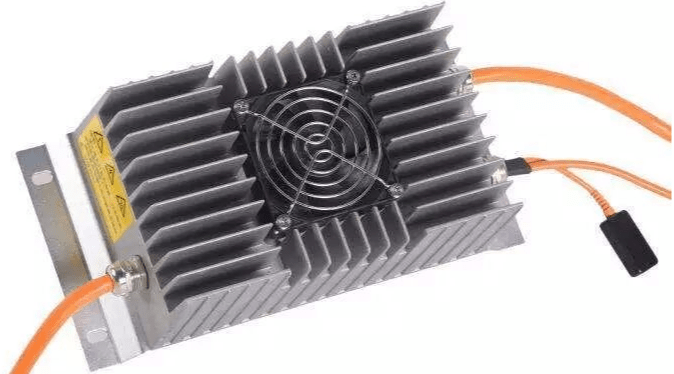

5. DC/DC

In new energy vehicles, DC/DC is a device that converts high-voltage direct current to low-voltage direct current. There is no engine in new energy vehicles, and the source of electricity for the whole vehicle is not all generators and batteries, but power batteries and batteries. Since the rated voltage of the vehicle’s electrical appliances is low voltage, a DC/DC device is required to convert high-voltage direct current to low-voltage direct current, so as to maintain the balance of vehicle power consumption.

6. OBC and DC/DC two-in-one controller

Affected by the layout of the whole vehicle, many cars now combine the two components of OBC and DC/DC into one component. This component is usually called a two-in-one controller. Its function is actually the two components of OBC and DC/DC. Combination of functions.

7. Electric compressor

The compressor of the traditional car is attracted by the electromagnetic clutch of the compressor, which prompts the engine to drive the compressor to operate. An electric vehicle has no engine, and its compressor is directly driven by a high-voltage power source. In order to distinguish it from the compressor of the traditional car, the air-conditioning compressor on the electric car is called an electric compressor here.

8. PTC heater

The heat source of the air conditioning heating system on traditional vehicles is the heat of the coolant introduced into the engine after cooling. This does not exist in new energy vehicles. Therefore, a special heating device is required. This device is called an air conditioner PTC. The function of PTC (Positive Temperature Coefficient) is heating. When the temperature is low, the battery pack needs heat to work normally. At this time, the battery pack PTC is required to preheat the battery pack.

9. High voltage wiring harness

The high-voltage wiring harness connects the various components of the high-voltage system as a medium for high-voltage power transmission. Different from the low-voltage wiring harness system, these wiring harnesses are equipped with high-voltage electricity, which greatly affects the stability of the high-voltage system of the vehicle. The safety of high-voltage wiring harness design is our main consideration.