M Series Connectors

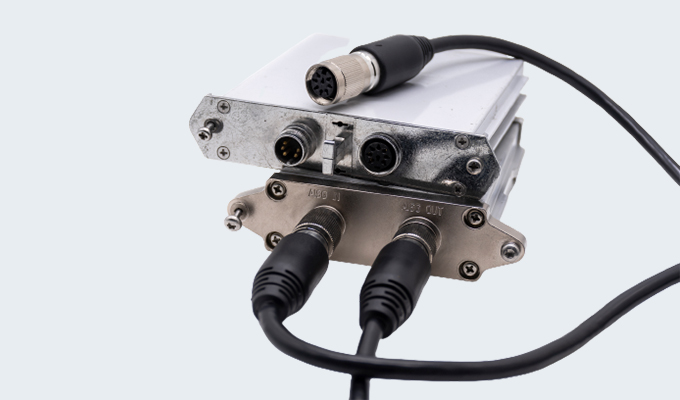

Are lightweight triplestart ratchet coupling type connectors designed for avionics, aerospace, Harsh Environment Connectors, security, motorsport and heavy duty applications.

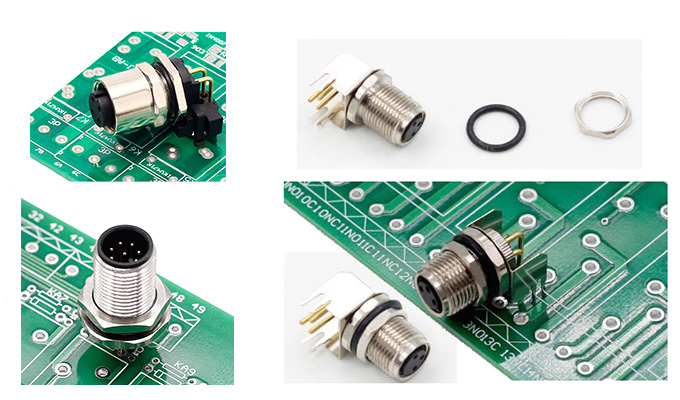

M connectors are circular connectors that are widely used in the aerospace, marine, communications, automotive, and heavy industries. Renhotec has introduced a range of M series connectors that offer flexible solutions for different applications and can meet the increasing demand for industrial automation and process control systems.

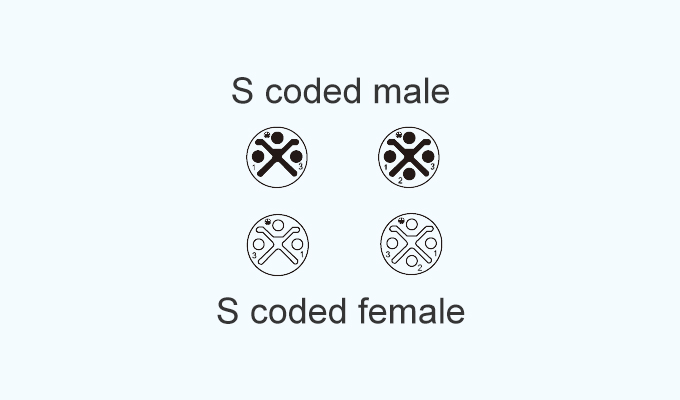

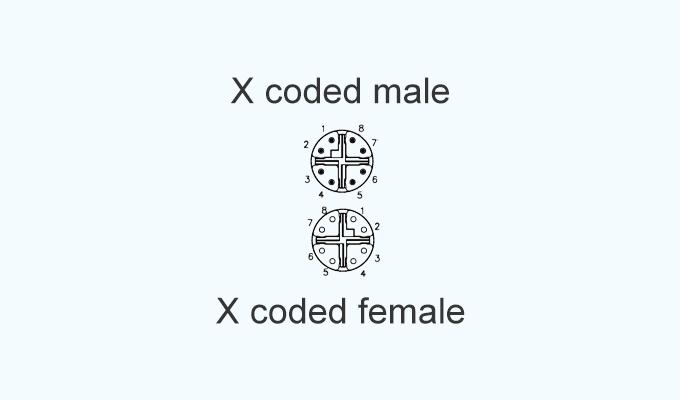

The M series connectors are available in various sizes, including M8, M5, M23, M16, and M12, and come in A, B, D, and X codes. Additionally, all M series connectors hold an IP67 rating, making them suitable for use under severe and challenging conditions.

When purchasing M connectors, customers have the option to choose connectors with or without cables. The cables are customizable based on length, and they can be made with PVC or PUR materials. With Renhotec’s M series connectors, customers can ensure reliable and secure connections for their devices, no matter the environment they are operating in.

The M5 circular connector product line features a threaded connection mechanism and an IP67 rating. Plugs and sockets for connecting electronics and sensors with compact, rugged features for use in harsh environments.

The M8 connector is designed for the device connection for sensor/actuator boxes,fieldbus modules and industrial controllers.

overmolded or supplied with attached wire leads. 360°EMC shielding is available as option.

With 8mm threaded joint, quick and easy mating and locking, even in places difficult to reach anti vibration locking design.

The M9 connector is a small connector. M9 connectors also have reliable connection performance and stable transmission speed, which can support high-speed data transmission and power transmission. Its protection level is usually IP67, which protects the device from water and dust, thus improving the reliability and stability of the device.

The M12 connector is designed for the device connection for sensor/actuator boxes,fieldbus modules and industrial controllers.

The M12 size is available in coding variants for all industrial lifelines – for power, signals and data.

With 12mm threaded joint, quick and easy mating and locking, even in places difficult to reach, anti vibration locking design.

The M16 circular connector is an industrial connector with a wide range of applications in robotics, automation equipment, sensors, medical equipment, power and control cables, and more. The connector usually adopts the mating sleeve structure, which has the characteristics of sealing, waterproof, dustproof and anti-interference.

M16 circular connectors are widely used in various industrial applications due to their versatility, robustness and reliability. It has the characteristics of waterproof, dustproof, high-speed transmission, etc.

The M23 connector is an industrial connector. Capable of transmitting high power and multiple signal contacts, it is well suited for applications where a large number of signals need to be bundled. m23 connectors are waterproof and dustproof for harsh environments and are typically rated to IP67.

M40 field-installable connectors support higher bandwidth while providing an IP67 rated solution for demanding applications.

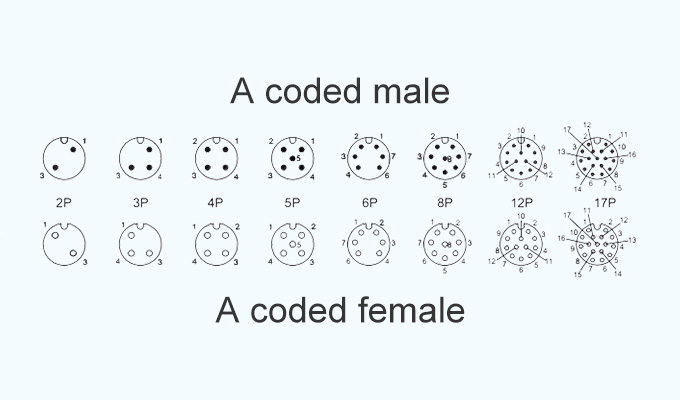

The A-coding provides a secure and reliable connection for power and signal transmission in harsh and demanding environments.

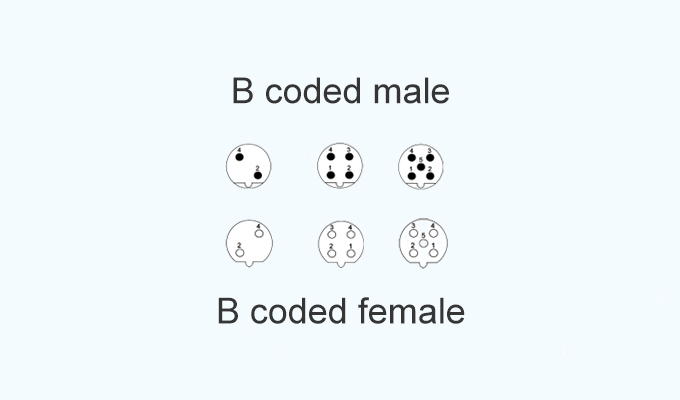

B coded is a type of circular connector used in a range of industrial and automation applications where there is a need for signal, data and power transmission.

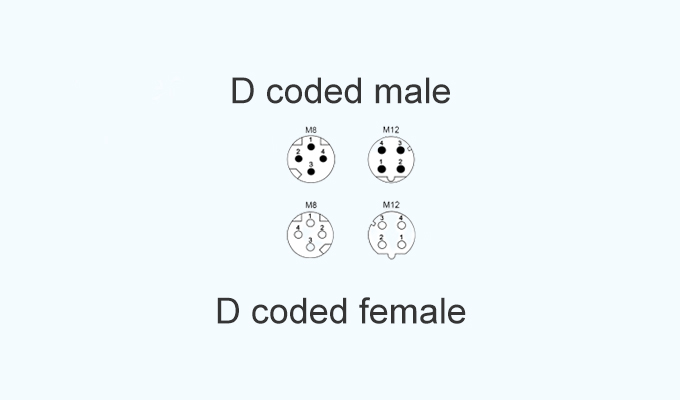

D coded is ideal for applications where there is a need for high-performance data transmission and reliable power supply in harsh environmental conditions.

The A-coding provides a secure and reliable connection for power and signal transmission in harsh and demanding environments.

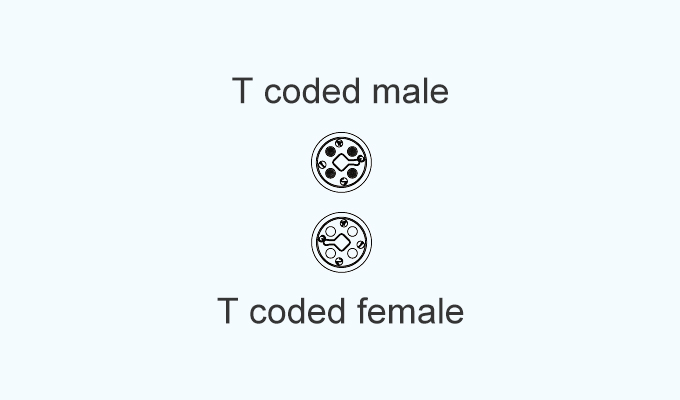

Circular connectors with T-coding are a type of industrial connector that is designed for use in harsh environments. These connectors have circular configurations with screw locking mechanisms, making them ideal for applications that require reliable and secure connections.

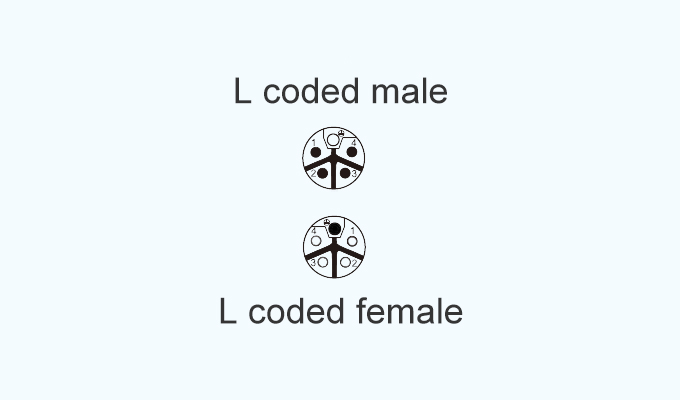

L-coded circular connectors are available in different sizes and number of pins, with some models supporting high-speed data transfer rates of up to 10Gbps. They are also designed to be waterproof and dustproof, with rugged casing that can withstand harsh environmental conditions.

X-coded circular connectors provide an ideal solution for high-speed and robust data transfer applications, especially those requiring waterproofing and resistance to harsh environments. They are widely used in automation, communication, and control systems where high-speed data transfer and robustness are critical.

To solder a wire to M connectors, strip the insulation from the end of the wire, insert it into the solder cup of the connector, bend the wire, apply heat using a soldering iron, and remove excess solder if necessary. It’s important to use the correct temperature and avoid melting the insulation. Solder termination creates a secure and reliable connection that can operate in harsh environments.

To install an M connector onto a PCB, mark the mounting hole locations onto the PCB and drill the holes. Insert the connector and solder the pins onto the PCB, ensuring a reliable electrical connection. Inspect the soldered connections and test the connector before use.

To make a screw joint with an M12 connector, strip the wires and insert them into the terminal block, tightening the screws securely without damaging the wires. Inspect the connection, and then thread the connector with the wires into the matching receptacle or threaded hole, turning it clockwise until the threads engage. Tighten the connector an additional quarter turn until it is firm, then test it to ensure a good electrical connection.